How Security Seals Function as Verification and Control Tools in Dairy and Tanker Operations

Posted by Steve Diebold

Security seals are widely used in dairy and tanker operations to support safety, quality, and accountability by providing visible evidence when access to a tank, valve, or hatch has occurred. This evidence is especially important in environments where direct supervision is limited and products move through multiple handoffs, routes, and processing stages. Each stage introduces risk if controls are not clearly verified, which is why seals help reduce uncertainty during transport and handling. Many drivers and operations managers question whether seals are worth the effort. This doubt often comes from viewing seals as passive accessories, rather than active controls. When seals are treated as afterthoughts, their benefits remain limited.

This guide focuses on how security seals add operational value in dairy and tanker environments beyond basic tamper detection. It explains how seals support quality assurance and food safety protocols, while reinforcing accountability across teams. The content also explores how seals contribute to tracking, documentation, and data consistency throughout operations. The goal is not to promote a specific product, but to demonstrate how seals function as practical tools in real-world workflows. Each section highlights a different functional role that seals can play. Together, these examples show how seals support process discipline and informed decision-making.

Security Seals as Verification Points in Tanker Operations

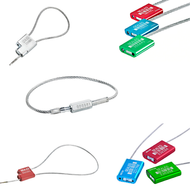

Security seals act as verification points throughout tanker workflows, including those supporting the dairy industry, by confirming that a valve, hatch, or access point remained untouched. This confirmation is critical between loading, transport, and delivery stages, where strong, application-specific seals like the barcoded steel globe seal – Model G1 provide clear, numbered evidence that a seal was applied and not substituted. Without seals, verification relies heavily on trust and assumption, whereas seals replace assumptions with visible evidence. This shift improves confidence in process integrity and makes verification objective rather than subjective.

In tanker operations, verification must be fast and clear. Drivers and inspectors cannot spend excessive time checking equipment, which is why versatile models, such as the adjustable medium strength pull tight seal Model AP25, are often used on valves and hatches where closures vary in size. A properly applied seal provides instant status recognition: if the seal is intact, the process continues; if it is broken, the process pauses. That pause creates accountability, because it requires review before movements continue.

Seals also help standardize verification across fleets. When placement and inspection are consistent, expectations are clear across drivers, wash operators, and receivers. Everyone knows what to look for, which reduces miscommunication and disputes during handoffs. Verification becomes a shared language across roles, and seals support that shared understanding through simple, repeatable visual cues and model-specific identification.

Supporting Food Safety and Quality Assurance Protocols

Food safety and quality assurance in dairy and tanker operations depend on clear verification and disciplined handling practices. Security seals support these goals by providing visible confirmation that critical control points remain secure throughout transport and handling. When used consistently, seals strengthen confidence in sanitation, compliance, and accountability.

- Confirming sanitation and protecting product integrity: Tanks and valves must remain secure after cleaning and inspection to preserve food safety. A properly applied seal confirms that sanitation has not been compromised before loading or transport, including the use of pull-tight plastic seals that support uniform application across repeated handling events. This confirmation helps preserve confidence in cleanliness, while supporting documented safety protocols that protect both product quality and brand reputation.

- Reinforcing consistent handling and compliance practices: Quality programs rely on predictable, repeatable handling procedures. Seals reinforce these practices by signaling when access occurs and making shortcuts visible. This visibility discourages unauthorized access and supports higher operational standards. Over time, consistent seal use becomes part of quality culture, shifting quality assurance from reactive checks to proactive control.

- Narrowing investigations and clarifying responsibility: When contamination or process deviation is suspected, seal status helps isolate responsibility quickly. Instead of questioning every step in the workflow, teams can review specific checkpoints where seal integrity changed. This focused approach saves time, reduces disruption, and improves the efficiency of quality reviews. Seals quietly support this clarity by providing simple, reliable reference points.

When integrated into food safety and quality programs, security seals strengthen verification, accountability, and confidence. Their value lies not in complexity, but in consistent application that supports disciplined processes and informed decision-making.

Using Seal Identification to Track Routes, Loads, and Processes

Security seals can carry operational information beyond basic tamper evidence, helping tanker operations manage routes and loads more efficiently when tamper evident seals are used as consistent reference points. Simple visual identification methods allow drivers and inspectors to confirm status quickly, without relying on paperwork. They use approaches such as color coding and consistent placement to reduce errors under time pressure.

Numbered seals add a straightforward tracking layer that links physical movement to records. Seal numbers can be recorded against load details, dates, or contracts, creating traceability across handoffs. This connection helps narrow timelines during audits or investigations, and reduces uncertainty when reviewing operations. Numbering allows seals to function as reliable reference points within the process.

Barcodes extend identification into digital systems without replacing physical inspection. Scanning seals at installation or removal creates time-stamped records that support compliance and centralized review. Used correctly, barcoding strengthens accountability through data capture, while remaining secondary to consistent visual inspection.

Coordinating Seal Use Across Drivers, Washes, and Facilities

Effective seal programs rely on clear coordination across everyone who interacts with sealed equipment. Drivers, wash operators, and facility staff each play a role in maintaining seal integrity, and consistency across these roles is essential, especially when commonly used products such as plastic security seals are applied across multiple control points. When expectations are aligned, seals function as reliable controls, rather than isolated checks.

Key elements of effective coordination include:

- Shared understanding of responsibilities so each role knows when to apply, inspect, or remove seals.

- Consistent training on proper application, inspection cues, and signs of tampering.

- Clear escalation procedures that define what to do when a seal is missing, broken, or irregular.

Training ensures expectations remain consistent across shifts and locations, reducing hesitation and improving response.

Procedures should clearly define every seal-related event to support disciplined use. Effective programs rely on:

- Standardized rules for seal installation, inspection, and removal, including products like fixed length plastic seals that benefit from uniform application.

- Required documentation to accompany each seal event.

- Routine reinforcement so sealing becomes part of daily workflow.

When coordination is supported by clear procedures and training, seals shift from passive objects to active operational controls. Shared discipline sustains reliability and strengthens accountability across the operation.

Documentation, Accountability, and Continuous Improvement in Seal-Based Systems

Documentation turns seal use into a verifiable process by creating clear records of responsibility and control. Recording seal numbers establishes traceability, especially when using barcoded seals, which allow seal activity to be logged and reviewed accurately. Documenting installation, inspection, and removal closes the accountability loop and provides context for every access event. Without consistent documentation, seals lose meaning and become isolated indicators rather than reliable controls.

Effective documentation systems must meet operational realities to remain sustainable. Overly complex logs or tools discourage compliance, particularly in fast-moving environments. Simple, consistent records, whether digital or manual, allow staff to document seal activity quickly and accurately. When documentation fits naturally into daily workflow, accuracy improves, and accountability is maintained without slowing operations.

Accountability strengthens when records are reviewed and used to guide improvement. Regular reviews help identify patterns, recurring irregularities, and process weaknesses before they escalate into larger risks. As operations evolve due to new routes, customers, or regulations, seal programs should adapt intentionally by reviewing available options across all security seals to ensure continued fit and effectiveness. Thoughtful expansion, supported by disciplined documentation and review, keeps sealing effective as a control, rather than simply increasing the number of seals in use.

Reliable Sealing Practices for Dairy and Tanker Transport

Security seals offer far more than basic tamper detection in dairy and tanker operations. They support verification, food safety, process visibility, and accountability. Their effectiveness depends on how they are applied and managed. Seals do not replace procedures or people. They reinforce them through visible evidence. When integrated correctly, seals strengthen confidence across operations. Their value lies in disciplined use.

American Casting & Manufacturing brings over 110 years of experience in supplying tamper-evident sealing solutions to dairy, tanker, and industrial operations worldwide. Our knowledge helps organizations choose seals that fit real operational needs. If you would like to discuss how sealing solutions can support your tanker or dairy operations, contact us Toll-Free at (866) 360-6748 or 516-349-7010, Monday through Friday from 9am to 5pm EST. You may also reach us at info@seals.com for guidance or support. With the right approach, security seals become tools for control, clarity, and confidence.