WHY CABLE SEALS ARE USED FOR RAIL TRANSPORT: THE ORIGIN OF MODERN HIGH STRENGTH CABLE SEALS

Posted by AC&M

Rail cars were among the first uses of security seals, well over a century ago. Seals made of lead and tin-plated steel were the original security seals for securing rail cars and their contents at that time.

Started in 1910 AC&M was a key part of the early production of seals for railways. Those seals are still made by AC&M today and are still in use. Steel band seals are used in many transport applications, including railways. Though gradually being replaced, lead seals are still also in use.

By the 1970s railways began to require stronger seals that would not be easily cut open, or accidentally broken. This resulted in the development of bolt type seals, now commonly used for intermodal shipping containers and trucks. That was followed by heavy duty cable seals which are becoming the preferred seal for many rail carriers. Cable seals are well suited to all types of rail cars including tankers, hoppers, and boxcars. In 2019 hopper cars and tankers made up over 2/3 of all rail cars in use, leading to the more common use of cable seals for rail shipping.

The modern cable seal is available with a range of sizes and strengths, and more marking options than ever. They fit more readily and are more adaptable to the variations of closures used today.

Like bolt seals, cable type seals can serve as both a tamper evident seal and a disposable heavy duty lock, for one-time use. The security level of a cable seal is high no matter what size or strength option you may choose. However, it is very important to follow proper practices in the use of cable seals and to make certain that cable seals are pulled as tightly as possible when locked.

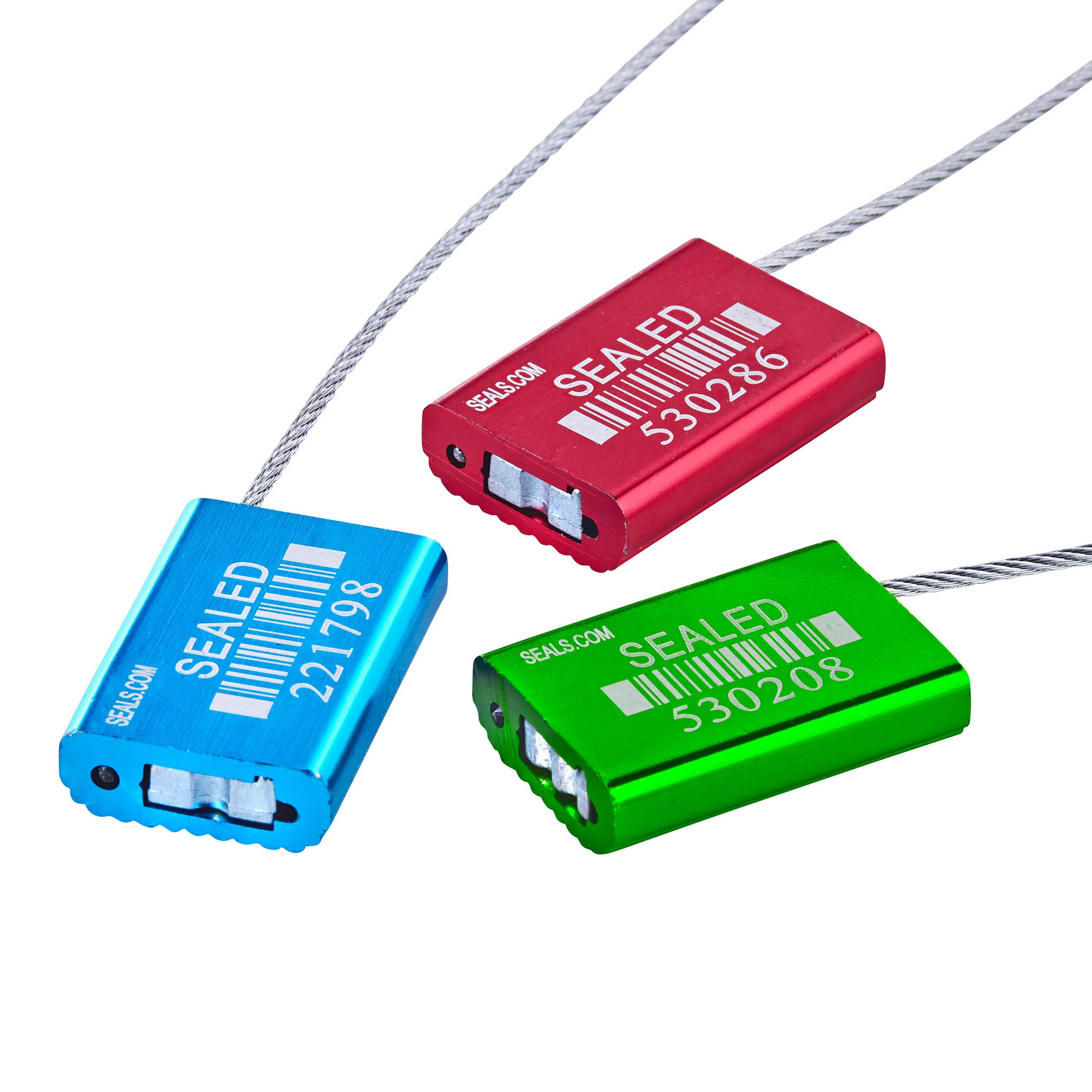

The original cable seals were made of all steel with stamped letters and numbers. They have evolved and are now also made often of aluminum with steel cable. These modern versions give the option of anodized colors plus more detailed laser markings including barcodes, logos and other customization. They also are more resistant to corrosion where the seals are used for extended times or in harsh conditions.

AC&M continues to offer both options of steel and aluminum cable seals. At our web site are details of the sizes, materials, and various options.

Cable seals are not limited to rail use and have become a favored seal for many other uses in transport, utilities, military, and petroleum operations, to name a few.

If you have questions about our seals or want information about using cable seals for rail cars or any purpose, contact us. AC&M serves thousands of seal users worldwide and is glad to assist with guidance, samples or pricing.

An experienced seal applications expert is available any time during business hours. Contact us at our main office and factory: info@seals.com or call 1-800-342-0333 in the US or 516-349-7010 from anywhere.

Or see our website www.seals.com for sales and service locations outside the US.