AC&M Cable Seals: Proven Security for the Atomic Energy Industry

Posted by Steve Diebold

In the highly regulated and security-sensitive world of atomic energy, every small detail matters. From transporting radioactive materials to securing nuclear waste containers, the systems used must be absolutely reliable and verifiable. One of the most critical components ensuring reliability is the tamper-evident cable seal. For over a century, American Casting & Manufacturing has been trusted by global nuclear organizations to design and produce cable seals that meet the strictest international safety and security standards.

AC&M’s legacy is built on precision, trust, and consistency. The company continues to innovate in the design of tamper-evident seals used across nuclear energy, waste management, and fuel transportation. Every seal produced reflects the company’s ongoing commitment to protecting high-value and sensitive assets. Through careful engineering, advanced testing, and adherence to international standards, AC&M’s cable seals ensure that every nuclear operation maintains absolute control over its materials and processes.

The Role of Reliable Sealing in the Atomic Energy Industry

The nuclear energy industry operates under some of the most stringent safety and regulatory frameworks in the world. Every stage, from fuel fabrication and power generation to waste containment, demands dependable tamper-evident seals that verify integrity and deter interference. A single compromised seal can result in significant security risks, regulatory violations, or safety incidents. This is why many nuclear facilities and government agencies rely on AC&M’s cable seals to protect their operations.

Tamper detection is not merely a precaution. It’s a necessity for compliance and accountability. Cable seals act as physical proof that containers, equipment, or storage units have not been opened or altered without authorization. By integrating advanced materials and production technologies, AC&M ensures each seal is traceable and verifiable. The company’s longstanding presence in the industry has made it a preferred supplier for power plants, transportation services, and inspection agencies handling sensitive nuclear materials.

The 3 Ultimate Basics of Cable Seals

Understanding what makes a cable seal effective begins with recognizing its fundamental components. These essentials determine how well a seal performs under pressure and maintains its tamper-evident features.

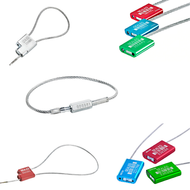

- Construction and Material: AC&M’s cable seals are made from high-tensile, corrosion-resistant stainless steel or galvanized steel. These materials provide exceptional strength and durability, withstanding exposure to radiation, harsh chemicals, and rough handling during transit. Each seal is crafted with a precision-machined locking body, ensuring consistent sealing strength and long-term reliability across demanding applications.

- Tamper-Evident Mechanism: A tamper-evident seal must clearly display any attempt to manipulate or remove it. ACM’s CL-99-332HD-24 Cable Seal and other models feature self-locking mechanisms and unique identification numbers that prevent substitution or reuse. Once locked, the cable cannot be withdrawn without visible damage, providing instant evidence of interference. This mechanism is a critical security layer for the nuclear energy sector, where traceability is essential.

- Compliance and Testing: Every AC&M cable seal undergoes rigorous testing to comply with global standards, including ISO 17712:2013 and C-TPAT. These certifications guarantee seals meet the highest benchmarks for tensile strength, shear resistance, and tamper detection. AC&M’s dedication to quality control ensures that every product leaving its facility meets international expectations for performance and security.

These three foundational principles, strong construction, visible tamper evidence, and strict compliance, form the basis of AC&M’s reputation for excellence in cable seal manufacturing.

The Proper Application of Cable Seals for Maximum Security

Even the best cable seals can only perform effectively if applied correctly. Proper installation, inspection, and maintenance are essential to ensure that each seal fulfills its purpose of deterring tampering and confirming integrity. AC&M’s 3/32" Adjustable Cable Seal – Model CL99-332 is a reliable choice for various high-security operations, including transportation and storage of nuclear materials. Designed for durability and flexibility, this model provides an adjustable fit that ensures a tight, tamper-evident closure in even the most demanding environments.

To properly apply a cable seal, the cable should be inserted through the locking chamber and pulled tight to eliminate slack. The locking mechanism must click firmly into place to provide a secure hold. Once the seal is locked, its unique identification number should be recorded in a tracking log or verification system. This process helps maintain a transparent chain of custody. It ensures that every seal applied can be traced back to its point of origin, enhancing accountability and compliance throughout nuclear operations.

Regular inspection is just as necessary as proper installation. Visual checks confirm that seals remain intact and show no signs of tampering or wear. Any irregularities, such as frayed cables or damaged locking bodies, should prompt immediate investigation. Through correct application and consistent monitoring, AC&M’s CL99-35SD cable seal and other models help maintain the integrity and safety of critical assets. Following these best practices ensures every seal performs reliably, providing lasting protection and confidence in high-security environments.

Certifications and Quality Assurance: The AC&M Advantage

AC&M’s credibility in the industry is built on a foundation of verified excellence. The company’s certifications demonstrate its commitment to international quality and compliance standards. Each certification ensures that AC&M’s seals meet or exceed global expectations for safety, reliability, and durability.

Some of the company’s notable credentials include:

- ISO 9001:2015 Quality Management Certification: Confirms AC&M’s commitment to consistent quality, ensuring every seal is designed, tested, and produced to the highest standards.

- ISO 17712:2013 and C-TPAT Compliance: Demonstrates adherence to international security standards for high security seals trusted by government and military organizations worldwide.

- United Nations and U.S. Government Registrations: Officially registered under number 6J629, enabling AC&M to supply reliable sealing solutions to federal and defense agencies.

- Founding Member of the International Seal Manufacturers’ Association (ISMA): Highlights AC&M’s leadership role in advancing global standards for seal manufacturing and industry safety.

AC&M also offers barcoded seals and bolt seals for applications requiring extra traceability and security. These achievements confirm AC&M’s position as a trusted manufacturer, serving thousands of clients across government, commercial, and industrial sectors.

End-to-End Manufacturing and In-House Expertise

What sets AC&M apart is its fully integrated manufacturing process. Every stage, from design and sourcing to production and shipping, is handled at the company’s headquarters in Plainview, New York. This approach allows complete control over quality, consistency, and security. Managing all operations in-house eliminates third-party risks and ensures traceability throughout the production chain.

This model also enables AC&M to provide customized sealing solutions tailored to specific client requirements. Whether for nuclear waste transportation, military logistics, or government compliance, AC&M’S engineering team collaborates closely with customers to design tamper evident seals that meet their exact specifications. Continuous innovation ensures that each solution remains ahead of evolving industry standards.

The comprehensive customer support system ensures seamless communication from order to delivery. Each department, quality assurance, logistics, engineering, and customer service, works collaboratively to uphold AC&M’s promise of security and reliability. This integrated approach safeguards products while strengthening long-term client partnerships.

Partner with AC&M for Trusted Sealing Solutions

The atomic energy industry demands precision, reliability, and absolute accountability. For more than 110 years, American Casting & Manufacturing has provided cable seals that meet those demands without compromise. The company’s dedication to innovation, integrity, and quality craftsmanship has earned it a reputation as a trusted partner to some of the world’s most sensitive industries.

When you work with AC&M, you gain access to decades of expertise, world-class engineering, and a team of professionals dedicated to your security needs. The company’s seals are more than just locking devices. They are assurance tools that protect assets, people, and the environment. If you would like to learn how AC&M’s sealing solutions can help secure your operations, contact us via email at info@seals.com or call toll-free (866) 360-6748 or 516-349-7010, Monday through Friday, 9 AM to 5 PM EST. Over a century of innovative, reliable American craftsmanship ensures that every seal embodies trust, quality, and a legacy of safeguarding critical industries.