Discover How We Can Help You Track and Control Your Seals

Posted by Steve Diebold

Effective security seals play a crucial role when properly applied, handled, and monitored or tracked. Adhering to these established standards ensures that each seal possesses distinct markings, facilitating record-keeping and tracking processes.

The tracking of security seals can range from a straightforward notation of the application and removal details to comprehensive information about various aspects of the seal's lifecycle. This encompasses details such as who handled it, inspection records, the purpose of use, physical characteristics, supplier information, and its journey throughout usage.

The extent of control and tracking employed is directly proportional to the value and risks associated with the specific purpose of the seal. For instance, a seal securing a container of nuclear waste undergoes meticulous and intensive control, while a seal on a tote of machine parts in a factory may necessitate minimal monitoring. Transportation stands out as the field with the most extensive range of tracking systems for seals.

In this blog, we will outline the fundamental approaches to seal control that can be implemented through forms or spreadsheets, either independently or integrated into an existing seal management program. These steps complement existing record-keeping practices for seal purchase and receipt, extending into the user's stock.

Managing Seal Distribution And Inventory

When doing seal management, a critical aspect revolves around the control and inventory of these security measures. This process often involves a designated individual, whether identified as a custodian or an auditor, who oversees the storage and issuance of seals.

The primary objective of implementing a form in this context is to document the recipients of the seals following their unpacking. Moreover, it may capture details about the intended purpose of each seal. This ensures transparency and accountability in the distribution process, facilitating a streamlined approach to seal utilization.

This approach not only enhances accountability but also contributes to the overall security of the tamper evident seal system. Allocating responsibilities with clarity and precision ensures a more efficient distribution of seals, minimizing the risk of unauthorized access or tampering.

Efficient Seal Installation Tracking

Before beginning the critical seal installation stage, an organized approach for monitoring and documenting needs to be established. In this regard, a form, distributed at the time of seal issuance with ample copies corresponding to the number of seals, becomes instrumental in capturing vital details.

This form includes a comprehensive description of the seal, identification of the installer, and specifics such as the location and timestamp of the locking event, along with the precise container, trailer, or closure on which the seal is applied. Flexibility is key, especially in scenarios where multiple individuals are involved in seal installation across diverse locations. The adaptability of this form accommodates the dynamic nature of the process, ensuring that each installation is meticulously recorded.

Beyond traditional paperwork, the integration of technology, such as a dedicated spreadsheet, streamlines the tracking process, offering a user-friendly and efficient solution. This combination of careful record-keeping and cutting-edge technology not only makes it easier to keep track of seal installations but also makes the security seal framework safer and more accountable overall.

Tracking for Seal Removal

Even if it's the last stage, the seal removal process still demands an organized way of keeping records. In fact, when the seal is opened, either by drivers, plant operators, or end-users, the removal form is used. This is essentially the same as the seal installation form.

This form serves as a detailed record of the seal's condition upon removal, capturing information at the destination or the conclusion of its intended use. Crucially, it ensures that the seal undergoes proper disposal or destruction post-inspection, reinforcing the integrity of the security protocol.

Simplicity is crucial when designing a removal form for its end users. For instances where a customer or recipient is handling a single seal, a streamlined version of the form can suffice. This approach facilitates seamless reporting back to the seal custodian or auditor. With the development of more advanced tools like a seal removal tool, seal removal is even more precise and safe.

Enhanced Seal Features For Efficient Monitoring

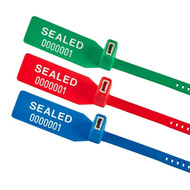

At AC&M, our extensive range of seals boasts advanced features designed to facilitate seamless monitoring and enhance security measures. The majority of our seals are equipped with distinctive marking capabilities, including letters, serial numbers, and a diverse array of colors, all serving as unique codes or indicators.

Moreover, our newer seal models offer additional marking options such as barcodes, optical codes, logos, location names, and designated writing spaces or security labels, catering to the specific marking needs of users. Customization goes beyond the seals themselves as we extend our services to packaging and labeling, supporting customers in effective handling, storage, and control of their seals. Our commitment extends to the meticulous tracking of numbers and markings sold, aiding customers in maintaining consistent series in repeat orders and preventing unwanted duplications.

While the array of forms and methods for seal control remains unique to each user, we refrain from delving into the limitless variables within any seal tracking program in this basic description. However, we invite you to reach out with any questions or for a more in-depth discussion of your specific needs. Our mission is to assist customers in optimizing their choices, including the utilization of advanced features such as smooth pull tight seals.

Get In Touch

Connecting with American Casting & Manufacturing opens the door to a wealth of experience and expertise garnered over 110 years in the seal industry, serving diverse users worldwide, including government, utility, military, and commercial entities. We extend a warm invitation to tap into our knowledge and explore the benefits we offer.

Our dedicated team of seal application experts is ready to assist you during business hours. Feel free to reach out to our main office and factory via email at info@seals.com or through our toll-free number, 1-800-342-0333 within the US or 516-349-7010 from any location. Whether you seek guidance, samples, or pricing information, we're here to help at your request.

For a comprehensive overview of our locations, products, and complete contact details, please visit our website at www.seals.com. Stay updated with our latest offerings and connect with us seamlessly.