Enhancing Aerospace Security With Tamper Evident Sealing Solutions

Posted by Steve Diebold

Safety isn't optional in the aerospace industry–it’s a requirement built into every process, product, and protocol. Whether flying passengers across continents or transporting valuable cargo at 30,000 feet, aviation depends on strict security measures to protect lives and materials. Among the often unsung heroes of these protocols are safety seals. These small devices carry a big responsibility: preserving the integrity of critical items, preventing tampering, and ensuring compliance at every checkpoint.

From the outside, seals may appear simple. However, their role in aircraft operations, cargo handling, and equipment protection makes them a crucial part of modern aviation. For over 110 years, American Casting & Manufacturing has led the way in developing reliable, high-quality sealing solutions trusted by aerospace professionals worldwide. This article examines the role of safety seals in enhancing aerospace security, from the tarmac to the sky, and highlights their crucial importance to aviation safety.

Securing the Unseen: How Seals Keep Aircraft Safe

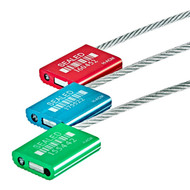

When passengers board a plane, they rarely see the inner workings of safety protocols beneath their feet. Behind the scenes, tamper-evident seals are applied to cargo bins, luggage compartments, and storage units to prevent unauthorized access. These cargo seals don’t just act as visual warnings, they serve as the first line of defense against threats or mishandling. If a seal is broken or removed, ground crews and airline staff are immediately alerted to investigate.

Seals also add a layer of trust in fast-moving airport environments. With hundreds of items being handled in a short period, security seals help ensure that every bag or container loaded onto an aircraft remains intact from origin to destination. This not only minimizes the risk of theft or contamination, but also enhances the traceability of valuable or sensitive goods.

A Closer Look at In-Flight Food Safety

Airline catering may seem like a behind-the-scenes operation, but maintaining food safety at 30,000 feet is a serious responsibility. Before meals reach passengers, food carts are sealed using tamper-evident plastic or pull-tight seals. These plastic security seal applications guarantee that the contents inside remain untouched from the catering facility to the cabin. A sealed cart signals to flight attendants and passengers alike that every meal is safe, fresh, and secure.

Beyond food safety, these seals also help airlines stay compliant with health and safety regulations. Catering companies and airline staff rely on quick-to-apply, easy-to-inspect seals to streamline their workflow. The use of custom seals, often color-coded or serialized, also enables detailed record-keeping and inventory control, helping aviation companies meet high standards with every flight.

Life-Saving Equipment Needs Reliable Sealing

Aircraft are equipped with critical emergency gear, including life jackets, oxygen tanks, medical kits, and defibrillators. Ensuring these items remain functional and untouched until needed is non-negotiable. That’s where durable safety seals come in. Applied to medical and emergency equipment, these seals confirm whether gear has been accessed or tampered with. If a seal is broken or missing, maintenance crews are quickly alerted to inspect and replace the item before takeoff.

American Casting & Manufacturing designs pull-tight and plastic strap seals built for reliability under pressure. Many of these are barcoded seals, offering a simple yet effective way to track usage, inspection dates, and replacement cycles. These lightweight, tamper-evident options ensure that safety gear is always flight-ready, giving airline crews and passengers peace of mind when every second matters.

Shielding the Engine Room: Seals in Aircraft Maintenance

Aviation engines are among the most complex machines in modern transportation, requiring exacting standards for maintenance and inspection. In this environment, safety seals serve both functional and procedural purposes. Technicians often apply seals to engine access panels, fluid reservoirs, and maintenance points to ensure that any unauthorized access or tampering is immediately visible. These security seals in the airline industry act as an integrity checkpoint, allowing airlines to verify whether maintenance has been performed correctly and whether the engine components have remained secure.

Engine seals must withstand extreme conditions, high temperatures, fluctuating pressure, and mechanical vibration. That’s why aerospace-grade seals are engineered from high-performance materials that deliver consistent performance.

Supporting Logistics with Smart Tracking

The aerospace industry depends on detailed logistics management. Cargo planes, supply chains, and maintenance hubs handle millions of parts and packages daily. Tamper-evident seals with tracking features, such as barcodes, serial numbers, or QR codes, offer a practical solution for monitoring the flow of goods. These security labels support inventory tracking, chain-of-custody protocols, and regulatory audits. When applied correctly, they create a digital fingerprint for each shipment or item, improving traceability and accountability.

Beyond tracking, smart seals also deter interference. The presence of a seal sends a strong message: any breach will be noticed. This serves as a deterrent for theft or internal tampering, particularly in high-traffic areas such as airport warehouses or aircraft hangars.

Why Seals Are More Than Compliance Tools

In aerospace, regulations set the standard, but quality sealing goes beyond compliance, it builds confidence. Tamper evident security seals do more than fulfill FAA or TSA regulations; they protect lives, prevent losses, and support operational readiness. Whether applied to an engine component, a food cart, or an emergency kit, the role of a seal is to maintain integrity. That’s why airlines, defense contractors, and aerospace service providers rely on high-quality seals that perform under pressure.

American Casting & Manufacturing understands that aviation demands more than off-the-shelf products. Each aircraft, cargo load, or security checkpoint presents unique challenges. Our team collaborates with aerospace clients to develop custom solutions, ranging from heavy-duty strap seals to lightweight pull-tight options tailored to specific use cases. It’s not just about meeting the standard; it’s about setting one.

Why Ac&M Is The Trusted Seal Provider By The Industry For Over A Century

For over 110 years, American Casting & Manufacturing has been a trusted name in security seal solutions for industries where safety, reliability, and precision are paramount. Our deep-rooted experience in aviation has enabled us to develop a comprehensive line of tamper-evident products specifically tailored to the challenges of air travel. Whether it’s sealing aircraft doors, logging maintenance activities, or safeguarding onboard equipment, our seals are engineered to meet the rigorous demands of today’s aerospace professionals.

Backed by decades of technical expertise and a strong customer-focused philosophy, our team is dedicated to helping organizations safeguard their personnel, cargo, and operations. We understand the unique needs of the aerospace industry and are proud to offer custom sealing solutions that align with both safety standards and operational goals. To learn more about our aerospace-ready seals, visit our About page or contact us directly to discover how we can support your specific requirements. Contact us today to speak with a knowledgeable representative. You can reach us toll-free at (866) 360-6748 or by calling 516-349-7010. For inquiries via email, please write to us at info@seals.com. Our team is available to assist you Monday through Friday, from 9 AM to 5 PM EST.